About Fuel Consumption System

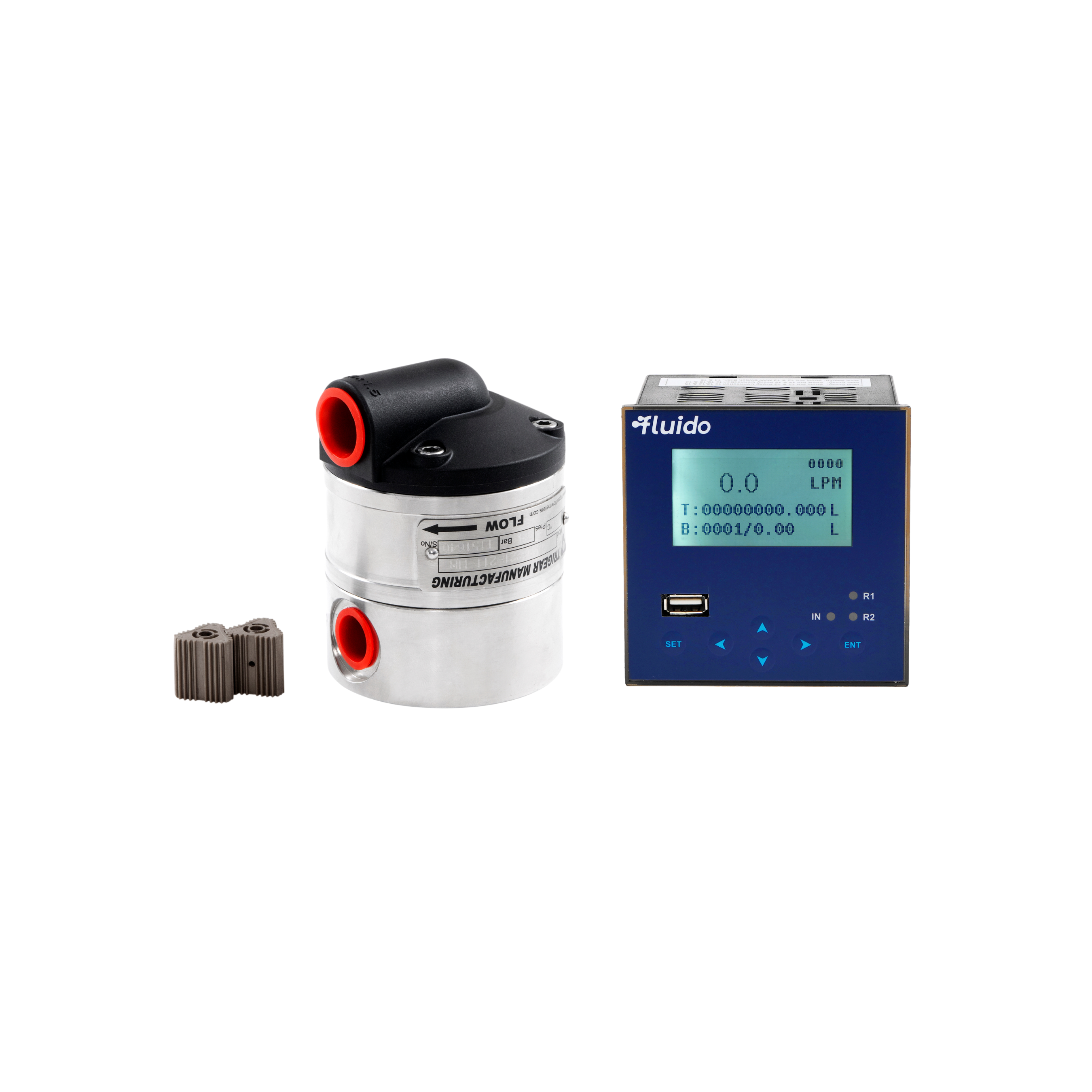

A Fuel Consumption Meter is made up of a positive displacement meter and manifolds. The monitoring system is carefully designed for the exact size of the diesel engine intake of any vehicles like buses, vans, construction equipment, agricultural machinery, or other diesel locomotives The Fluid sense Fuel meter is a perfect solution for independent measurement of inflow and outflow of diesel fuel for calculating the net consumption of diesel engines, boilers, kilns and furnaces. Our legendary oval gear Flow meters guarantee high accuracy and repeatability of the net fuel measurement.

Operation Principal

Fluid Sense Fuel Consumption system is a Single Solution to suit the net consumption requirements of any Power Engines. The unit is provided with two separate Flow sensors each for measuring the Diesel input and the return output to and from the Engine. The return fuel is throughly deareated before being measured by the Retum Flow sensor. A Micro controller based Display with accurately measures the differential of both Flow sensors to provide the net consumption of the engine. A 12/24V DC Powered LCD display with RS 485 Serial Output is most ideal solution for interfacing the Unit with BMS or SCADA Systems.

Features

Suitable for all types of power Engines

Engine Rating from 100-3000 KVA

Accuracy Guaranteed over any Flow range

Independent Flow sensors for Input and Return Fuel. No requirement of any Air

Separator for return fuel demarcation

Operation on 12/24V DC Supply from Cranking Battery

RS 485 Serial Data Output for external interface.

Specifications

- Flow Range (LPH): 5 - 50000

- Accuracy (+1-): 0.5% of reading

- Service: HSD / LDO / MDO

- Operating Temperature 0 -85°C

- Output: Modbus RS-485 RTU

- Display with supply, return flow and consumption with stock fuel in tank

- Indication of total fuel supply and return line from and to engine

- Indication of time of fuel supply and return

- Fuel measurement with high accuracy positive displacement flow meter

- Power supply: 230VAC/24VDC